Newsroom

Rotary kiln tyre lubrication

2017-07-20 | Editor:

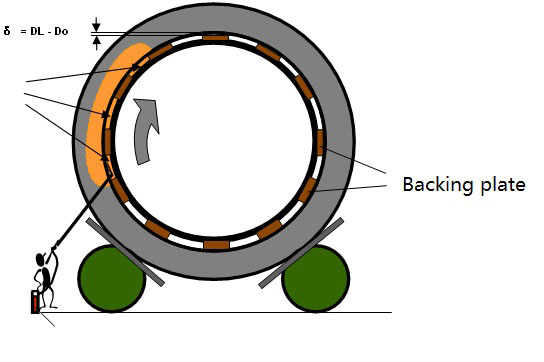

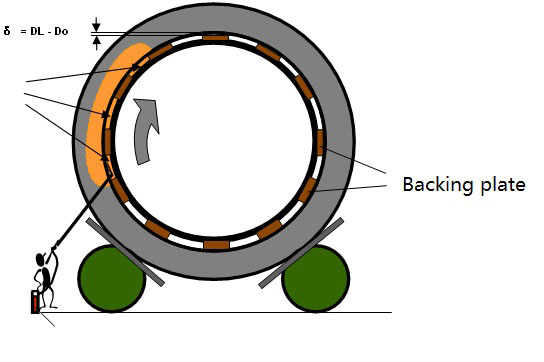

Rotary kiln tyre plays a supporting role. There is a certain gap between the tyre and the kiln body, and during the operation process of rotary kiln, kiln tyre and the kiln cylinder body move relatively to form sliding friction pairs. So the lubrication between tyre inner surface and its corresponding backing plate must be given adequate attention. If the lubrication in this area is not enough or the lubrication is improper, it will cause accelerated wear of the backing plate and affect the stability of the kiln, so that the stability of the kiln brick will be reduced or even fallen off, resulting in a decrease in kiln production.

I. Features of friction pairs between kiln tyre and kiln body:

Sliding friction pair between the tyre inner surface and the backing plate is characterized by high temperature, low speed, and heavy load. And the combustion temperature in the friction area closed to the combustion zone can reach 300℃. In addition, the cylinder and the material are very heavy, and the relative movement between tyre and cylinder is quite slow, so the kiln tyre is in low-speed and heavy-load operation conditions. Therefore, the choice of a solid lubricant is more proper for this friction zone.

II. Requirements for rotary kiln tyre lubrication

1.High temperature resistance. The lubrication point temperature is up to 300-400℃, lubrication agent is required to make slight smoke at 300℃ temperature, and won’t come into spontaneous combustion at 400℃, and there is no production safety hazard;

2.Strong anti overload ability, good adhesion.

3.Long time to keep lubrication effect.

4.Good permeability. Because the kiln tyre has a certain width, and there is backing plate between tyre and cylinder, the lubrication must have good permeability to fully lubricate all parts of tyre.

5. Good security.

III. Lubrication method (Manual)

The lubricant is sprayed from the axial direction to inner surface of kiln tyre and inner surface of side baffle. Do not spay it on kiln body surface resulting waste.

III. Lubrication method (Manual)

The lubricant is sprayed from the axial direction to inner surface of kiln tyre and inner surface of side baffle. Do not spay it on kiln body surface resulting waste.

IV. Other lubrication method

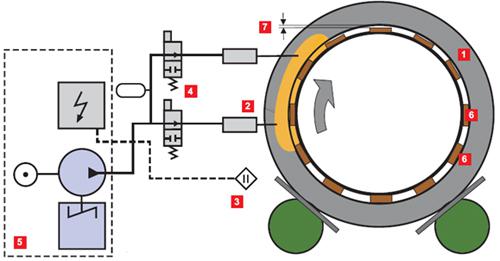

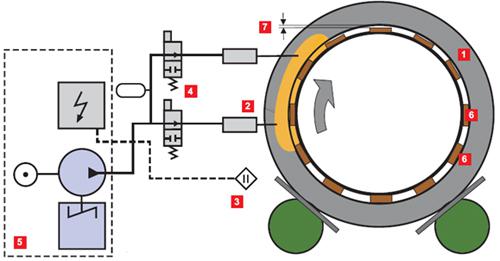

Manual lubrication method has some deficiencies. During the normal operation of the rotary kiln, the high temperature near kiln tyre is not conducive to the work of the operator. In addition, the operator needs some operating skills to spray the lubricant into the lubrication point accurately and adequately. Therefore, automatic lubrication is another option.

Schematic diagram of automatic spraying system

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:CHAENG coal mill roller cover, coal mill parts manufacturer

Next:How to avoid fault during the operation of rotary kiln support roller

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958